Understanding the Basics: Definitions and Relationships

Let’s start by clarifying what each term means and how they connect. Soft robotics is an emerging field of robotics that focuses on creating robots and robotic components using flexible, compliant materials. Unlike traditional rigid robots made of metal and hard plastics, soft robotics leverages materials like silicone, rubber, fabric, and shape-memory alloys. These materials allow for more natural movement, adaptability, and safety.

A soft robot is a robot built primarily using these soft materials. It can bend, twist, and deform in ways that rigid robots cannot, making it ideal for interacting with delicate or irregularly shaped objects and operating in unpredictable environments. Think of a soft robot as a flexible machine that can navigate through tight spaces or safely interact with humans.

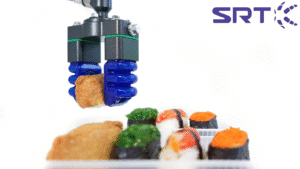

Now, a soft gripper is a specific component of a soft robot (though it can also be used independently). It’s the “hand” of the robot, designed to grasp and manipulate objects. Just like a human hand uses the flexibility of skin and muscles to hold everything from a delicate egg to a heavy tool, a soft gripper uses its soft structure to adapt to the shape of the object it’s gripping.

In short, soft robotics is the overarching field, soft robots are the complete machines within that field, and soft grippers are important tools or parts of these machines. They all rely on the same principles of flexibility and adaptability but exist at different levels of complexity – from a single component (soft gripper) to a complete system (soft robot), both falling under the umbrella of the soft robotics discipline.

The Magic of Soft Grippers: How They Work and Why They Matter

Soft grippers operate on the principle of compliance. Instead of using rigid fingers with fixed shapes, they often have flexible “fingers” or structures that can conform to the object’s surface. For example, some soft grippers are made of silicone with internal air chambers. When air is pumped in or out, the chambers expand or contract, causing the gripper to close around an object. This is similar to how an octopus uses its flexible tentacles to grasp prey – the tentacles wrap around the target, adapting to its unique shape.

One of the key advantages of soft grippers is their safety. In traditional manufacturing, rigid robotic grippers can damage delicate objects or pose a risk to human workers if there’s a collision. Soft grippers, because they’re made of squishy materials, are much gentler. Imagine a fruit-packing factory: a soft gripper can pick up a ripe peach without bruising it, something a rigid gripper might struggle with.

They’re also incredibly versatile. Soft grippers can handle objects of various shapes, sizes, and textures – from a tiny marble to a jagged rock, or a soft stuffed animal to a hard metal part. This adaptability makes them useful in situations where the objects to be handled are unpredictable or vary widely, which is common in many real-world applications.

Applications of Soft Robots and Soft Grippers

In Manufacturing and Industry

Traditional industrial robots are powerful but rigid, often confined to caged areas to keep human workers safe. Soft robots, on the other hand, can work alongside humans. For instance, in automotive assembly plants, a soft robot with a soft gripper can gently handle delicate electronic components for car interiors, reducing the risk of damage. In food processing, soft grippers are used to handle everything from bread rolls to eggs, ensuring products aren’t crushed during handling.

In Healthcare and Medicine

The medical field has embraced soft robotics for its potential to perform delicate tasks. Soft surgical robots can navigate through the body’s soft tissues more safely than rigid ones. Imagine a soft robotic arm used in minimally invasive surgery that can bend and twist through narrow spaces in the abdomen, reducing tissue damage. Soft grippers here might be used to hold and manipulate tiny organs or sutures with precision.

Soft exoskeletons, another type of soft robot, are helping people with mobility impairments. These wearable devices use soft materials to assist with walking, providing support without the bulk and rigidity of traditional exoskeletons.

In Consumer Electronics and Daily Life

Think of a soft robot designed to help around the house. A soft gripper could be part of a robotic vacuum that not only cleans but also picks up and places small objects back in their proper spots, adapting to the shape of each item. In electronics, soft robots can be used to assemble delicate devices like smartphones, where precision and gentleness are key.

In Exploration and Research

Soft robots are also making waves in exploration. For example, in underwater exploration, soft robotic fish or octopus-like robots can move through water more efficiently and quietly than rigid machines, allowing them to study marine life without disturbing it. In space exploration, soft robots could navigate the uneven and fragile surfaces of other planets, where a rigid robot might get stuck or damaged.

The Future of Soft Robotics: Trends and Possibilities

Material Innovations

Scientists are constantly developing new materials for soft robotics. Some are working on self-healing materials, so if a soft gripper gets a small tear, it can repair itself. Others are exploring biodegradable materials, which would make soft robots more environmentally friendly, especially important for applications like ocean cleanup, where a soft robot might eventually decompose harmlessly.

Integration with Advanced Technologies

Artificial intelligence (AI) is set to enhance soft robots and grippers. Imagine a soft gripper that uses AI to “learn” how to grip different objects. It could analyze the shape and texture of an object and adjust its grip in real-time, becoming more skilled over time, much like a human hand improves with practice. Sensors are also being integrated into soft robots, allowing them to “feel” pressure, temperature, and texture, making them more responsive and intelligent.

(Bionics)Inspiration

Nature is a great teacher for soft robotics. Scientists are looking at animals like octopuses, squids, and even worms for inspiration. An octopus has no bones, yet it can manipulate objects with incredible dexterity. Mimicking such biological systems could lead to soft robots that are even more agile and adaptable. For example, a soft robot inspired by a worm could navigate through small pipes or cracks, useful for search and rescue missions in collapsed buildings.

Broader Accessibility

As the technology advances and costs come down, we can expect to see soft robots and grippers in more everyday applications. From assistive devices for the elderly to educational robots for kids, the versatility and safety of soft robotics make them suitable for a wide range of users. Imagine a soft robotic companion that can help a senior citizen with daily tasks, using a soft gripper to hold a cup of tea without spilling it, or a toy robot that’s safe for children to play with because it’s made of soft, non-toxic materials.

Conclusion

Soft grippers, soft robots, and soft robotics are transforming the way we think about machines. From the gentle touch of a soft gripper handling a fragile object to the adaptability of a soft robot navigating a complex environment, this field combines innovation with practicality. As materials get smarter, integration with AI and sensors deepens, and inspiration from nature continues, the possibilities for soft robotics are endless. Whether in industry, healthcare, or our daily lives, these flexible machines are set to play an increasingly important role, making our world safer, more efficient, and more connected.