Introduction

Industrial PLC programming is the backbone of modern automated manufacturing and industrial processes. PLCs (Programmable Logic Controllers) are robust digital computers designed to perform control functions, typically for machinery and factory assembly lines. With efficient PLC programming, industries can achieve enhanced productivity, reduced downtime, and greater system reliability.

What is PLC Programming?

PLC programming involves writing instructions for a PLC to control machines and processes. These programs are typically written in one of five standard programming languages defined by IEC 61131-3:

- Ladder Logic (LD) – Visual language resembling electrical relay logic.

- Function Block Diagram (FBD)

- Structured Text (ST)

- Instruction List (IL) (now deprecated)

- Sequential Function Chart (SFC)

Each language has unique advantages depending on the complexity and requirements of the control system.

Why is PLC Programming Essential in Industry?

PLC programming is essential for:

- Automating repetitive tasks such as assembly line operations

- Real-time monitoring of equipment and sensors

- Reducing human error in critical processes

- Improving safety by integrating fail-safes and emergency controls

- Enabling predictive maintenance through data logging and diagnostics

Common Applications of Industrial PLC Programming

Industries across the globe rely on PLCs in sectors such as:

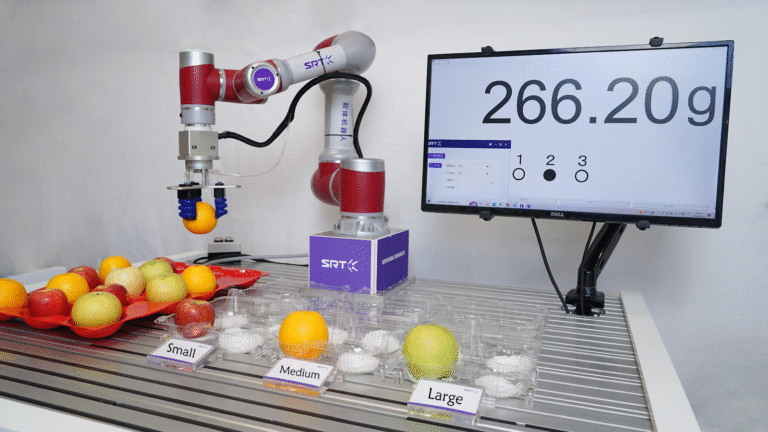

- Manufacturing: Assembly lines, robotic arms, conveyor belts

- Food & Beverage: Batch processing, bottling, packaging

- Water Treatment: Pump control, filtration systems

- Energy: Power distribution, turbine control, SCADA systems

- Automotive: CNC machines, automated painting, welding

Benefits of Professional PLC Programming Services

Outsourcing PLC programming to experienced professionals offers:

- Custom solutions tailored to your equipment and workflow

- Reduced downtime during upgrades or new installations

- Improved system integration with HMIs, SCADA, and ERP systems

- Code optimization for faster and more reliable operations

- 24/7 support and troubleshooting expertise

Key Considerations in PLC Programming

When implementing or upgrading your PLC systems, consider:

- Scalability: Can the system grow with your production needs?

- Compatibility: Does it integrate well with your existing equipment?

- User interface: Is the HMI intuitive for operators?

- Security: Are there protections against unauthorized access?

- Compliance: Does the system meet industry and safety standards?

Future Trends in PLC Programming

As Industry 4.0 continues to evolve, so does PLC technology. Key trends include:

- Remote programming and monitoring

- Integration with IoT and cloud platforms

- AI-assisted diagnostics

- Wireless PLC communication

- Cybersecurity enhancements

Partner with Experts in Industrial PLC Programming

Whether you need a new automation system or want to optimize your existing setup, working with skilled PLC programmers ensures long-term success. A well-programmed PLC system not only boosts efficiency but also enhances safety and sustainability in your operations.

Contact us today to learn how our PLC programming services can transform your industrial automation process.

Visit U Magazine for more informative content!